Who can use nanoICE

Catch

Seafood processors

Aquaculture producers

Produce companies

WHAT’S IN IT FOR YOU

We solve long-lasting challenges in food preservations

nanoICE’s unique features address multiple challenges for seafood harvesters and producers delivering up to 15% improvement in post-harvest yields.

Easy to use machines

• Pumpable ice solution

• Both super-cooled water and ice

• Intuitive touchscreen interface

• Easy and accurate hose delivery

• No more shoveling

Customer service

• Easy to install

• Simple to maintain

• Collect sensor data

• Built-in troubleshooting

• Can be remote controlled

Tangible ROI

• Longer product shelf life

• More sellable weight

• Increased profit margins

• Return on capex in 18 months

Flexible solution

• Small and modular machines

• Less energy and less refrigerant

• Use in various industries

• Customizable for your needs

35% better pedicel (stem) retention

In 2011, nanoICE partnered with the Washington State University in order to perform an extensive test on Skeena & Rainer cherries to evaluate the ways both nanoICE and flake ice affect such gentle products.

The cooling tests showed that nanoICE quickly and dramatically reduced fruit temperature. Further analysis revealed better color grade, visual appearance and stem retention in fruit treated with nanoICE.

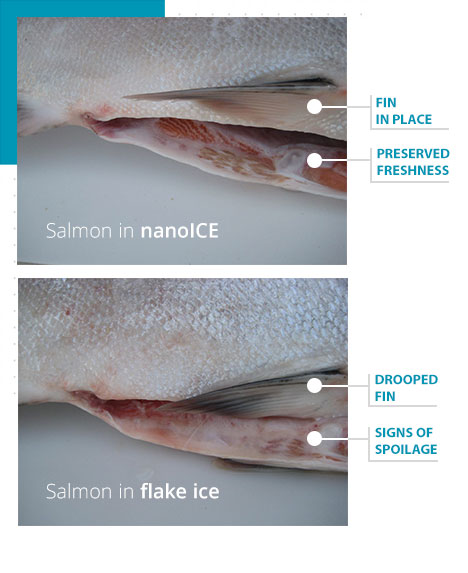

The 72-hour fish test

The nanoICE team self-conducted a quick experiment where we stored salmon for 3 days in two separate containers – one filled with flake ice and the other filled with nanoICE.*

In just 72 hours, the salmon treated with flake ice showed signs of advanced bacterial infection and discoloration. The fin had slipped down and had pulled away from the flesh, which documented for ongoing dehydration and enzymatic breakdown. Additionally, there was a pool of drop loss, containing largely protein.

On the other hand, the salmon we placed in nanoICE did not have any signs of drip los or colour discoloration. The fin had stayed in its original position. And since nanoICE is liquid, it had also penetrated the inner side of the fish, keeping its core cool inside and out.

* Third-party validation needed to prove results.

TESTIMONIALS

What our clients say

TESTIMONIAL

I’ve used NanoICE for 5 years. Cooling is much faster and more consistent.

The fish quality is better, the buyers are happier, and we don’t have to shovel flake ice anymore.

nanoICE is unique to the industry; we have not experienced results like these with any other ice product.

Principal usage guideline for nano-ice

Optimizing the inherent benefits of nano-ice

Chilling of fresh/live fish in either fish farming prior to killing or in reception areas in holding tanks onboard fishing vessels prior to bleeding/gutting

5-10% thin nano-ice solution at -1,2°C to -1,5°C, depending on salinity in the seawater source, is used for this purpose of preventing heat buildup in the raw material in holding tanks / fish reception areas, ideally quickly lowering the raw material temperature from start temperature, without exceeding lower temperatures than +1 to +1,5°C since fish has not been bled or processed.

Maximum recommended storage: 24-30 hours, or until temperatures in fish/ice water exceeds +1°C, without drainage / depending on insulation of holding tanks.

Ice used straight from the machine and/or pumped from an OPTIONAL 1-5t nano-ice storage buffer tank containing the 5-10% thin nano-ice solution in larger volumes on demand.

Chilling of fresh fish after killing/bleeding/gutting/de-heading/grading of farmed fish and/or fresh fish at sea in holding/ RSW/ Helix tanks

Helps bleed the fish better and faster thus also preventing heat buildup in the raw material during this important and heat sensitive processing stage.

Use 15-20% medium thin nano-ice solution at -1,7°C to -2,0°C is used for this purpose of preventing heat buildup and continue/maintain the rapid pre-chilling of the raw material to as close to -0,5°C, prior to either fresh long terms storage in thick nano-ice ( 1-3 weeks as shown in C ), processing and/or blast/plate freezing.

Maximum recommended storage: 36-48 hours without drainage, or until temperatures in fish exceeds -0°C and all the ice has melted. Then either drain all melted ice and re-apply 15-20% nano-ice solution and preserve fish below -0,5°C for another 24 hours / or process the fish / or place fish in thick nano-ice for storage as explained in C) below.

Ice used straight from the machine and/or pumped from an OPTIONAL 1-5t nano-ice storage buffer tank containing the 15-20% medium thin nano-ice solution in larger volumes on demand.

Storage of fresh whole fish (ideally also pre-chilled as in A+B) in drained fish boxes or tubs for 1 – 3 weeks onboard fishing vessels or during transportation in refrigerated cold storage/shipping containers prior to processing

Storage temperature in cold storage/fish hold ideally set to -1°C in order to preserve the nano-ice for the maximum period of time, since nano-ice will cover the fish surface 100% but DOES NOT NEED TO MELT at +2-3°C as conventional ice in order to chill the fish.

Make sure to use ONLY DRAINED TUBS OR BOXES.

35-45% medium thick to thick nano-ice solution at -2,2°C to -3,0°C is used for this purpose, to chill the fish as quickly as possible to the desired and most ideal core storage temperature of -0,5 to -1°C.

For 3-5 days fresh storage: If ice is used straight from the machine without using an agitated nano-ice storage tank, produce ice in the maximum thickness at 35-40% ice concentration.

A setup with a nano-ice system without a nano-ice storage/buffer tank can be suitable for long-line boats and 2-3 day boats, when delivering thick nano-ice into fish boxes or tubs, as the catch is fed evenly into the process from the line. Also in processing facilities when the machine is set to constantly feed thin to medium thick ice into chilling/holding tanks in the processing area.

For 1-3 weeks fresh storage: Thick 40-45% drained nano-ice pumped from a nano-ice buffer/storage tank onto fish in boxes or tubs.

A setup with a nano-ice system with a nano-ice storage/buffer tank is required/highly recommended for all fishing vessels receiving their catch in large volumes each time, like trawlers, gillnetters etc. The machine ́s ice production capacity is set to re-fill the nano-ice storage/buffer tank between catches. (…during 3-5 hour towing etc.)

Storage of fish products (fillets, loins etc.) in thick and drained nano-ice solution for transportation to market in corrugated/Styron boxes (for retail)

Here, the nano-ice storage buffer tank is an essential component of the nano-ice system. The nano-ice buffer tanks are designed to lower the salinity in the ice, increase the ice% and minimize the water content in the ice prior to use in “retail” boxes when required.

The thickest nano-ice at 40-45% ice concentration is produced in the machine and delivered into the nano-ice tank. Temperature in the ice when entering the tank is estimated at -2,8°C to -3,2°C and salinity at 3% on average.

When pumped into the “retail” boxes, the ice % will be closer to 50 to 55%, salinity between 1 to 1,5% and temperature climbed to -2,4°C to -2,7°C.

If the “nano-ice Quality and Cold-Chain” from A to D is practiced, the fresh fish products will ideally be at – 0,5°C when placed in the “retail” boxes (super-chilled) and less ice should be required for a normal transport of 3-5 days to market. If transport time is 6-9 days it becomes even more important to carry out the protocol from A to D above and only use slightly more nano-ice in the boxes.